- Home Page

- Company Profile

-

Our Products

- Marine Rubber Fender

- Rectangular Marine Fender

- Hollow Rubber Fender

- Key Hole Type Fender

- D-Shaped Tug Boat Fender

- V/W Shaped Marine Rubber Fender

- Cylindrical Rubber Fender

- Hollow Tug Boat Rubber Fender

- Cylindrical Type Fenders

- Square Rectangular Tug Boat Fender

- Cell Fenders

- Arch Rubber Marine Fender

- Square SD Rubber Fender

- Square SO Rubber Fenders

- Black Marine Rubber Fender

- Ship Fender

- D-Shaped Marine Rubber Fender

- Cylindrical Tug Boat Fender

- Rubber Fender

- Customized Gaskets

- Rubber Gasket

- Industrial Rubber sheets

- Silicone Rubber Sleeves

- Silicone Rubber Tubes

- Rubber O Ring

- Silicone Rubber Transparent Tube

- SWR Rings

- Silicone Rubber Strips & Square

- Silicone Rubber Gasket

- Rubber Bellow

- Molded Rubber Products

- Sponge Rubber Components

- Rubber Liners

- Silicone Rubber Fittings

- Precision Rubber Parts

- Silicone Articles

- Moulded Sheets

- Rubber Handle

- Rubber Bumper

- Rubber Discs

- Rubber Buffer

- Rubber Pipe Support Rings

- Black Rubber Pads

- Black Mounting Pads

- Rubber Moulds

- Rubber Compound

- Rubber Mounting Pads

- Rubber Ball For Vibro Machine

- Neoprene Pad

- Silicone Rubber Soap Mold

- Extruded Rubber Profiles

- EPDM Rubber Extrusion

- Rubber Seal

- Rubber Grommet

- Rubber Products

- Rubber Speed Bump

- Silicone Rubber Sponge Strip

- Industrial Rubber Product

- Anti Vibration Mounts

- Air Craft Wheel Stopper

- Silicone Rubber Band

- Rubber Tube

- Sponge Rubber Strip

- Silicone Rubber Washer

- Rubber Caps

- Rubber Casting Liners

- Marine Rubber Fender

- Extra Links

- Contact Us

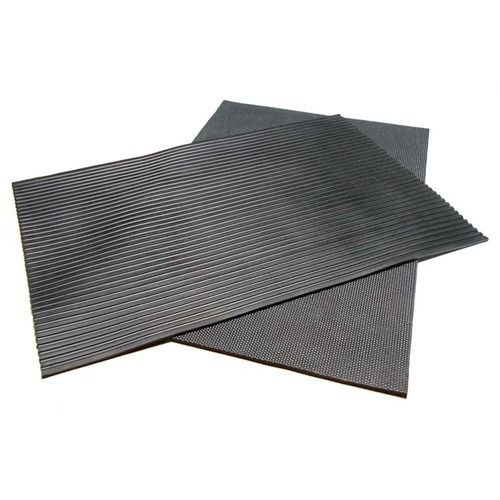

Moulded Sheets

850 INR/Kilograms

Product Details:

- Nitrogen Content (%) Negligible

- Product Type Moulded Sheet

- Style Plain/Embossed finish

- Components Solid homogeneous material

- Thickness 2 mm to 50 mm

- Length Up to 2000 mm

- Part Type Sheet

- Click to view more

X

Moulded Sheets Price And Quantity

- 850 INR/Kilograms

- 100 kg Kilograms

Moulded Sheets Product Specifications

- Rubber or customized elastomer

- Low thermal conductivity

- 0.2 mm

- Up to 2000 mm

- Sheet

- 2 mm to 50 mm

- Solid homogeneous material

- Plain/Embossed finish

- Moulded Sheet

- Negligible

- Black, Red, Grey, or as per requirement

- Varies per sheet size and thickness

- <2%

- Min 33 kg/cm

- Up to 1000 mm

- Industrial insulation, electrical purposes, gaskets, machinery protection, and flooring

- 605 Shore A

- Resistant to weather, abrasion, acid, and alkali

- Less than 1%

- Custom dimensions available

- Negligible

- 0.05 Gram per cubic centimeter(g/cm3)

- Smooth/Matte

- High compressibility (~20%)

Moulded Sheets Trade Information

- Mumbai

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- 2000 Kilograms Per Week

- 12-18 Days

- Standard

- All India

- ISO 9001:2015

Product Description

Recognized as a trustworthy entity in the international market, we are manufacturing, supplying and exporting Rubber Moulded Sheets. Along with using as an insulation material, these sheets are also used to provide cushioning effect in different furniture items and upholsters. We make sure that entire range is thoroughly checked for its dimensional consistency and flawlessness so that clients are not availed with any defective piece. These Rubber Moulded Sheets are high in demand for the below mentioned features:

Features of Rubber Moulded Sheet :

- Highly flexible

- Shock absorber

- High thermal insulation

- Chemical resistant

Versatile Industrial and Electrical Applications

Moulded Sheets are widely employed for effective insulation, gasketing, flooring, and machinery protection across various industries. Their high resistance to environmental factors and customizable sizes ensure the perfect fit and reliable performance for both standard and highly specific use cases.

Robust Physical and Chemical Qualities

These sheets are engineered from solid, homogeneous rubber or elastomer, offering high tensile strength, excellent hardness (605 Shore A), minimal ash and volatile matter, and near-zero nitrogen and water absorption. Each sheet undergoes stringent quality checks, ensuring it endures demanding conditions while maintaining its protective and insulating properties.

Tailored to Unique Project Requirements

With custom width, thickness, length, and finish options, our Moulded Sheets cater to a variety of application-specific needs. Whether you require plain or embossed textures, special colors, or different sizes, our manufacturing expertise delivers solutions that support optimal functionality and convenience for every project.

FAQs of Moulded Sheets:

Q: How are moulded sheets typically used in industrial settings?

A: Moulded sheets primarily serve as insulation, gaskets, protective flooring, and shielding for machinery in industrial applications. Their durability and resistance to harsh chemicals, weather, and abrasion make them ideal for heavy-duty environments where longevity and protection are paramount.Q: What benefits do these sheets offer for electrical insulation?

A: Due to their low thermal conductivity, negligible water absorption, and high resistance to both acids and alkalis, moulded sheets provide effective electrical insulation. This helps prevent electrical leakage and protects both components and personnel in various electrical installations.Q: Can I request custom sizes and finishes for my project?

A: Yes, moulded sheets can be manufactured to your specific requirements, with widths up to 1000 mm, lengths up to 2000 mm, and thicknesses between 2 mm and 50 mm. Available in either plain or embossed finishes and tailored colors, each sheet can be adapted to suit your unique application.Q: What is the manufacturing process for these moulded sheets?

A: The sheets are produced using advanced moulding techniques that ensure homogeneity and precision. Careful selection of rubber or elastomer materials guarantees performance characteristics such as high compressibility (around 20%), superior hardness, and robust tensile strength, followed by rigorous quality control.Q: When should I choose a plain finish versus an embossed finish?

A: A plain finish is ideal for smooth applications such as lining surfaces or electrical insulation, while an embossed finish provides enhanced grip or non-slip properties, making it suitable for flooring or scenarios where slip resistance is crucial.Q: Where are these sheets exported and supplied from?

A: As a prominent exporter, manufacturer, and supplier based in India, we cater to both domestic and international markets, providing high-quality moulded sheets to a wide range of industries worldwide.Q: What are the key advantages of using these moulded sheets in construction or renovation projects?

A: The sheets offer high resistance to physical and chemical wear, adaptability to custom sizing, and reliable insulation and protection. Their negligible water absorption and low density further enhance performance, making them a practical and cost-effective choice for long-term durability in construction or refurbishment applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese