- Home Page

- Company Profile

-

Our Products

- Marine Rubber Fender

- Rectangular Marine Fender

- Hollow Rubber Fender

- Key Hole Type Fender

- D-Shaped Tug Boat Fender

- V/W Shaped Marine Rubber Fender

- Cylindrical Rubber Fender

- Hollow Tug Boat Rubber Fender

- Cylindrical Type Fenders

- Square Rectangular Tug Boat Fender

- Cell Fenders

- Arch Rubber Marine Fender

- Square SD Rubber Fender

- Square SO Rubber Fenders

- Black Marine Rubber Fender

- Ship Fender

- D-Shaped Marine Rubber Fender

- Cylindrical Tug Boat Fender

- Rubber Fender

- Customized Gaskets

- Rubber Gasket

- Industrial Rubber sheets

- Silicone Rubber Sleeves

- Silicone Rubber Tubes

- Rubber O Ring

- Silicone Rubber Transparent Tube

- SWR Rings

- Silicone Rubber Strips & Square

- Silicone Rubber Gasket

- Rubber Bellow

- Molded Rubber Products

- Sponge Rubber Components

- Rubber Liners

- Silicone Rubber Fittings

- Precision Rubber Parts

- Silicone Articles

- Moulded Sheets

- Rubber Handle

- Rubber Bumper

- Rubber Discs

- Rubber Buffer

- Rubber Pipe Support Rings

- Black Rubber Pads

- Black Mounting Pads

- Rubber Moulds

- Rubber Compound

- Rubber Mounting Pads

- Rubber Ball For Vibro Machine

- Neoprene Pad

- Silicone Rubber Soap Mold

- Extruded Rubber Profiles

- EPDM Rubber Extrusion

- Rubber Seal

- Rubber Grommet

- Rubber Products

- Rubber Speed Bump

- Silicone Rubber Sponge Strip

- Industrial Rubber Product

- Anti Vibration Mounts

- Air Craft Wheel Stopper

- Silicone Rubber Band

- Rubber Tube

- Sponge Rubber Strip

- Silicone Rubber Washer

- Rubber Caps

- Rubber Casting Liners

- Marine Rubber Fender

- Extra Links

- Contact Us

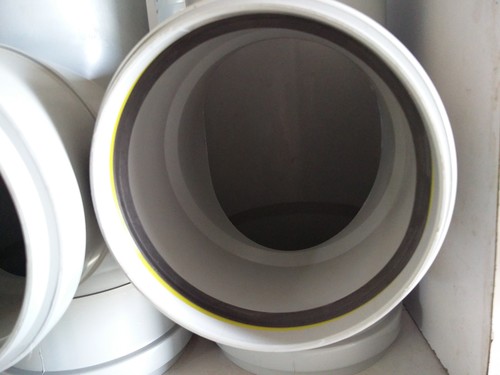

Round SWR Rubber Ring

3.00 - 4.00 INR/Piece

Product Details:

- Width Customizable or standard as per pipe size (commonly 10-20 mm)

- Rubber Type EPDM/Natural Rubber Blend

- Size Available as per SWR pipe diameter (63 mm, 75 mm, 90 mm, 110 mm, etc.)

- Resistance level Good resistance to water, mild acids, and alkalis

- Thermal Conductivity Very low

- Natural Rubber Yes (may be blended with synthetic rubber)

- Usage & Applications Used for sealing joints in SWR (Soil, Waste & Rainwater) drainage and plumbing systems to prevent leakage.

- Click to view more

X

Round SWR Rubber Ring Price And Quantity

- 10000 Piece

- 3.00 - 4.00 INR/Piece

Round SWR Rubber Ring Product Specifications

- Non-flame retardant

- Black

- 4 mm - 8 mm (varies with size)

- <1% (low water absorption)

- 10 MPa

- Rubber Ring / Gasket

- 0.5 mm

- High flexibility, Leakproof seal, Long service life

- Dependent on size; lightweight

- 1.25 Gram per cubic centimeter(g/cm3)

- -30C to +90C

- Available as per SWR pipe diameter (63 mm, 75 mm, 90 mm, 110 mm, etc.)

- Good resistance to water, mild acids, and alkalis

- Customizable or standard as per pipe size (commonly 10-20 mm)

- EPDM/Natural Rubber Blend

- Used for sealing joints in SWR (Soil, Waste & Rainwater) drainage and plumbing systems to prevent leakage.

- <0.5%

- Pipe Fitting Seal

- Smooth

- Very low

- Yes (may be blended with synthetic rubber)

- 60-65 Shore A

- 1%

- 20% - 30%

- Round

- 1.5%

- Circular (matches circumference of application)

- Varies (matches SWR pipe diameter)

- High-quality EPDM/Natural Rubber

- Single-piece circular ring

Round SWR Rubber Ring Trade Information

- Mumbai

- 1000 Piece Per Day

- 1 Week

- Standard

- All India

- ISO 9001:2015

Product Description

SWR Rubber Ring

We are leading manufacturer of SWR Tight Fix O Ring or Push Fit Ring is a system that is joined together by simply pushing or tightening the spigot into socket end This requires no threading or solvent for joining The spigot end is held firmly in the socket by the reinforced yellow seal provided in the groove

The available size ie 50 mm 75 mm 90 mm 110 mm 160 mm 200 mm We can also give different colour ie Blue Green White along with Black as per customer requirement

Features Benefits of Round SWR Rubber Ring

100 leakproof joints

High flow rates no choking

High degree of dimensional accuracy

UV stabilized

Quick and convenient installation

Cost effective

Advantages

The Yellow Seal sits in the groove of the socket and is permanently positioned by the advanced comoulded plastic unlike conventional rubber rings which have a tendency to come out during fitment Superior Yellow Seal Technology No solvent cement is required to make joints These are manufactured at par with international standards and are strictly monitored for quality and consistency

Push fit Systems Offer the Following Advantages

Simply push and fit fast and easy installation

No solvent cement required for making joints cost effective

High pressure bearing capacity joint pressure tested at 5 kgcm2

Yellow Seal technology allows thermal expansion and contraction

High flow rates no choking

Accurate and perfect dimensional control

Specification

Size

75 mm 110 mm

Brand

RANELAST

Hardness

60 5 Shore A

Diameter

75 mm110 mm

Material Grade

Natural Rubber

Shape

Round

Application

For SWR Pipe

Designed for Lasting Seals in SWR Systems

Our Round SWR Rubber Rings serve as trustworthy sealing solutions for drainage and plumbing pipes, preventing leaks and maintaining system integrity. The rings excellent resistance to aging, UV, ozone, and multiple chemicals enable them to endure outdoor exposure and tough environments. With high elongation at break and robust tear strength, they consistently retain their shape and reliability under pressure, making them ideal for both residential and commercial drainage installations.

High-Quality Rubber for Reliable Performance

Crafted from a select blend of EPDM and natural rubber, these rings feature low water absorption, smooth surface finish, and tight dimensional tolerance. The flexible design accommodates pipe movement without loss of seal, while their push-fit installation streamlines onsite fitting. Each ring meets strict standards for ash content, nitrogen, and tensile strength, delivering durable, leakproof service in varied climates and applications.

Flexible Sizing for Every Application

Available in customizable or standard widths and diameters (including 63 mm, 75 mm, 90 mm, and 110 mm), these rings are tailored to match SWR pipe sizes effectively. Their lightweight profile and single-piece construction make handling and installation hassle-free. Whether used in large-scale infrastructure or residential upgrades, the rings adapt seamlessly to the requirements of modern pipe systems.

FAQs of Round SWR Rubber Ring:

Q: How are Round SWR Rubber Rings installed in drainage and plumbing systems?

A: The installation process is straightforwardsimply push-fit the rubber ring into the pipe joint, ensuring a snug fit around the circumference. This easy method requires no special tools or adhesives and guarantees a leakproof seal in SWR drainage and plumbing systems.Q: What makes these rubber rings suitable for outdoor and long-term use?

A: These rings are engineered with excellent UV, ozone, and weather resistance, allowing them to withstand prolonged exposure to sun, rain, and environmental variations. Their high aging resistance ensures a reliable, durable seal even under challenging outdoor conditions.Q: Where can Round SWR Rubber Rings be used?

A: Designed for SWR (Soil, Waste, and Rainwater) drainage applications, these rings are ideal for sealing pipe joints in both residential and commercial plumbing and drainage systems, especially where robust, weather-resistant sealing is essential.Q: What benefits do these rings offer over standard pipe seals?

A: They provide a leakproof seal with exceptional flexibility, high tear strength, and superior shape retention under pressure. The rings are resistant to standard domestic chemicals, have low water absorption, and are crafted for a long service life, making them a cost-effective choice.Q: When should I replace an SWR rubber ring?

A: Replacement is recommended if you observe visible deformation, excessive wear, cracking, or compromised seal performance. However, due to their robust construction and weather resistance, these rings generally offer extended longevity compared to standard seals.Q: Are these rubber rings compliant with safety and environmental standards?

A: Yes, the rings are RoHS compliant and manufactured with carefully selected materials that ensure low ash and volatile matter content, making them safe and environmentally responsible for domestic and commercial use.Q: What sizes and thicknesses are available for the Round SWR Rubber Rings?

A: Rings are produced to match a range of SWR pipe diameters, including 63 mm, 75 mm, 90 mm, and 110 mm. Thickness varies from 4 mm to 8 mm depending on the selected size, with width options customizable between 1020 mm to suit specific pipe connections.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese